“PT-1946MC” can perform fitting and torsion stress test specified in common test method of former ISO 594 and ISO 80369 Part 20.

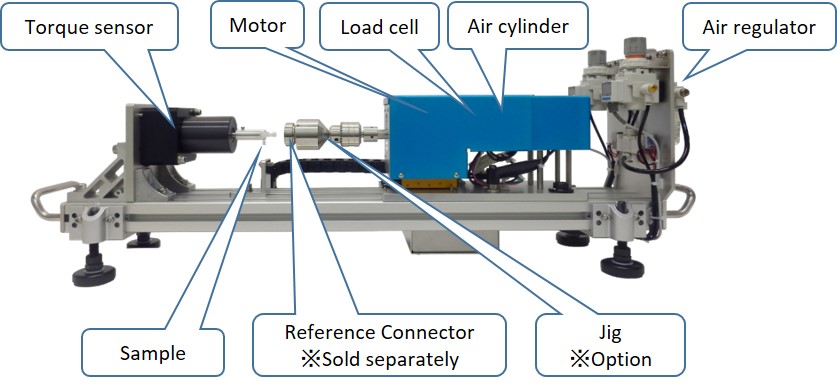

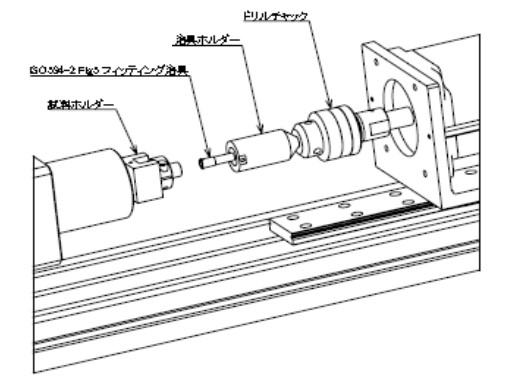

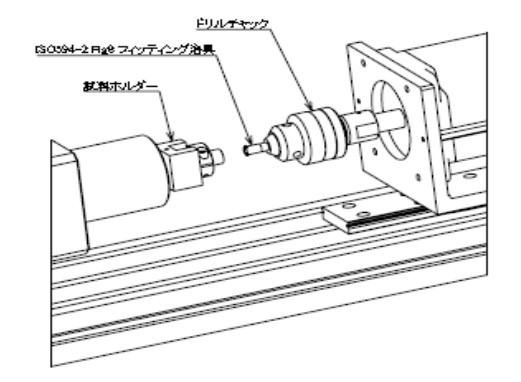

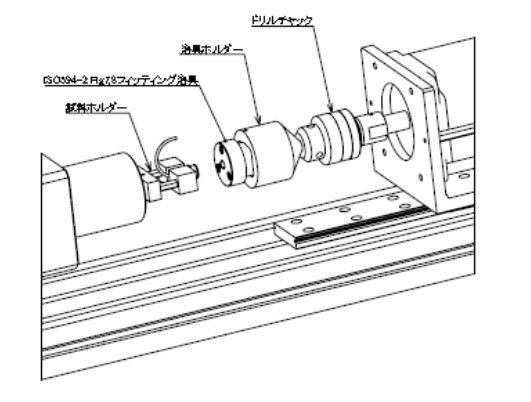

Fitting and torsion stress test is performed by fixing the fitting gauge on the driving unit side and the medical connector on the torque sensor side and twisting while pressing the fitting gauge and the medical connector. Pressing is done by the electro-pneumatic regulator and the pressing load value is measured by the load cell. Torsion is done by the drive unit and the torsion torque is measured with the torque sensor.

Medical connector measurement system “PT-1946MC” |

Configuration

|

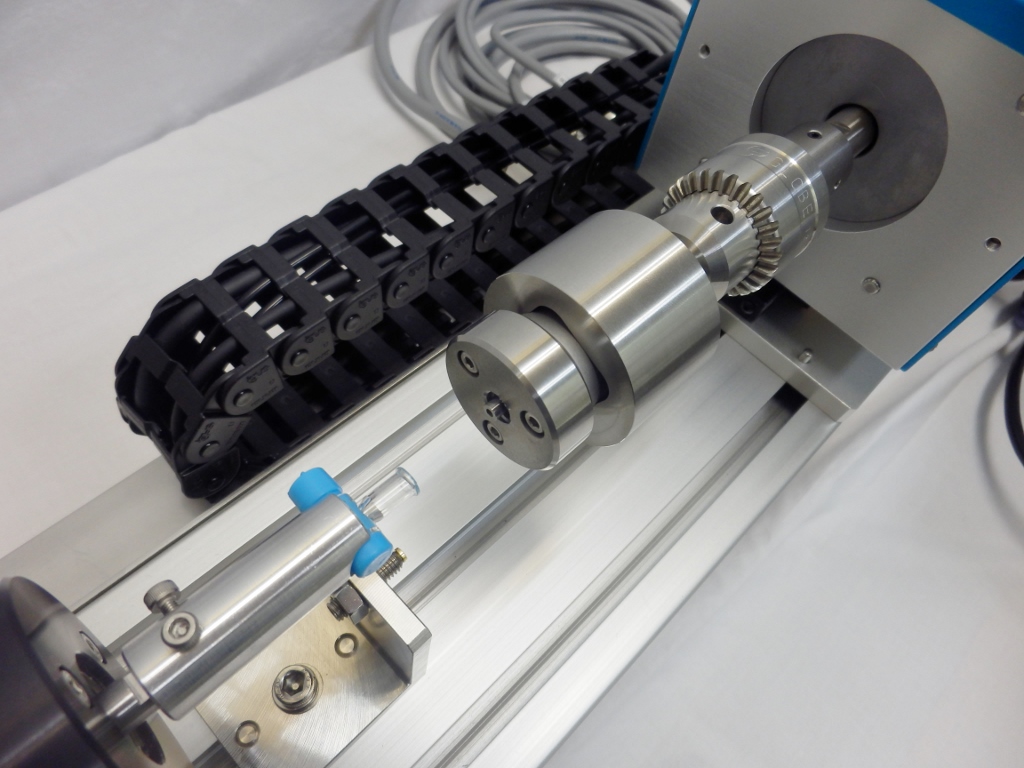

Before the test |

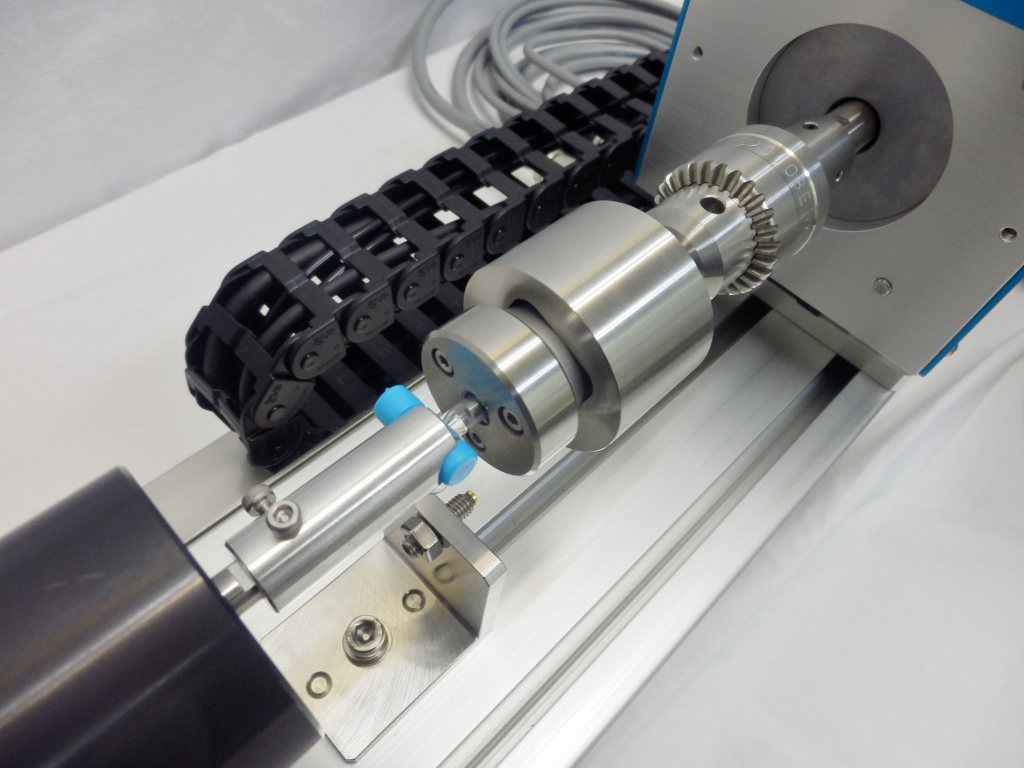

During the test |

Feature

●”PT-1946MC” can perform fitting and torsion stress test specified in common test method of former ISO 594 and ISO 80369 Part 20.

・fitting and torsion stress test specified of ISO80369-3 and ISO8039-6 , ISO80369-7

・ISO80369-20:Common test methods

・former ISO 594

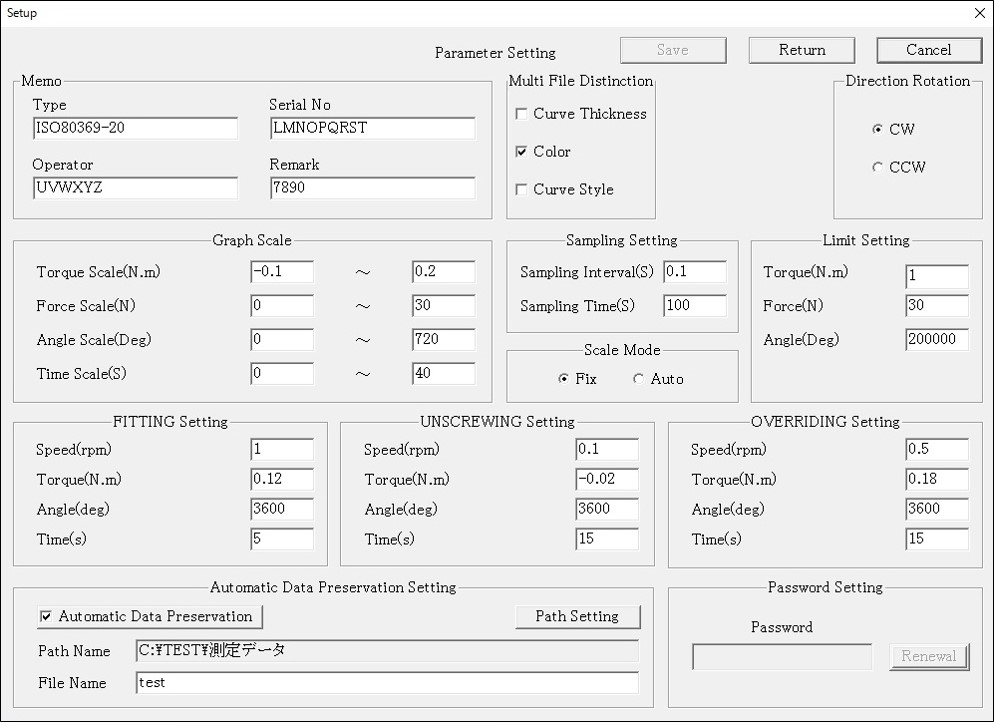

●Panel screen.

A panel screen is provided on the screen of the computer to display torque, load and angle.

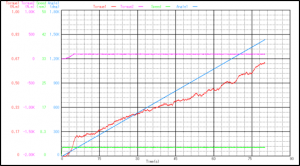

●Graph screen.

Torque, load, angle curve is displayed.

Sampling is performed at specified time intervals.

●Save measurement data as CSV file in text format.

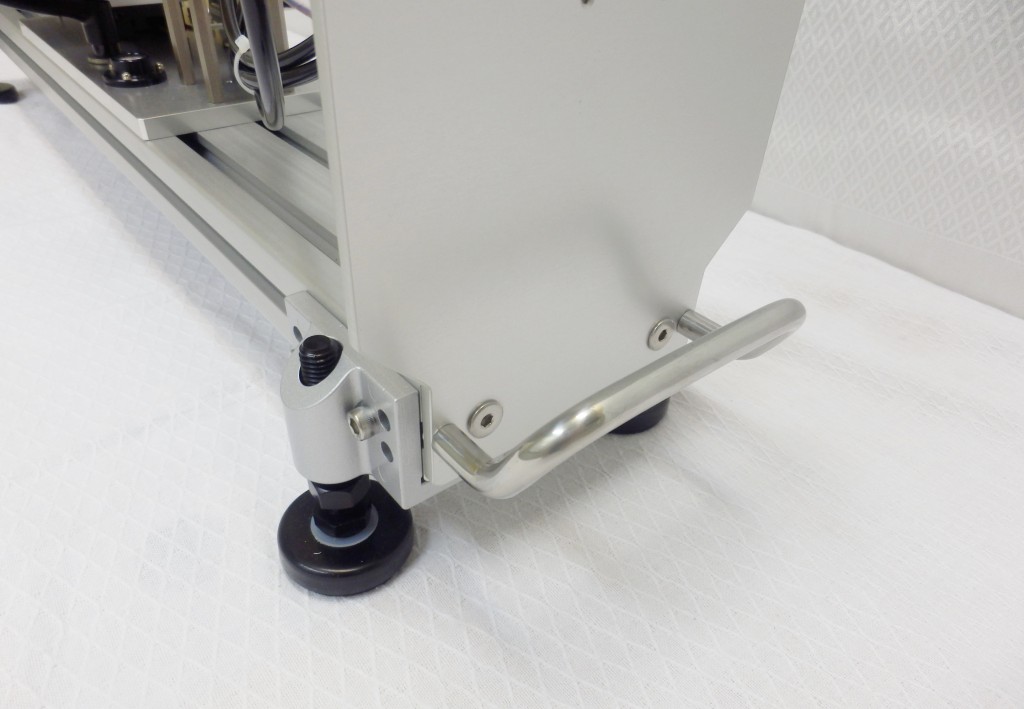

●Compact and lightweight.

●Handy handle is attached for easy carrying.

Specification

Torque sensor 1Nm

| Torque resolution | 1mNm |

|---|---|

| Total torque accuracy | ±1%±3Digit |

Lord cell 100N

| Load resolution | 0.1N |

|---|---|

| Load Accuracy | ±1%±3Digit |

Option

A reference connector is required to perform tests conforming to ISO 80369 and former ISO 594 using this device.It is possible to prepare an optional jig for connecting this unit to the reference connector.

※No reference connector is attached to this.Please purchase separately.

≪Jig Production Example≫

Former ISO594-2 Fig.5 |

Former ISO594-2 Fig.6 |

Former ISO594-2 Fig.7.8 |

Corresponding test item

Items in red can be tested with this unit.

※Leak test is not supported.

ISO80369

Small-bore connectors for liquids and gases in healthcare applications.

Part20:Common test methods.

| TEST METHOD | TEST METHOD | |

|---|---|---|

| FITTING | TEST | |

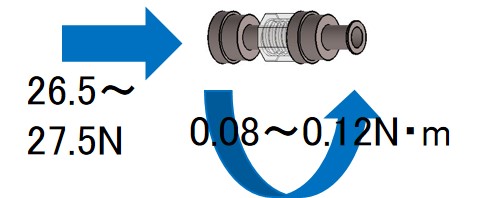

| Annex B Leakage by pressure decay TEST METHOD | Axial force:26.5N~27.5N Torque:0.08Nm~0.12N Time:5s~6s | (Abridgement) |

| Annex C Falling drop positive-pressure liquid leakage TEST METHOD | (Abridgement) | |

| Annex D Subatmospheric-pressure air leakage TEST METHOD | (Abridgement) | |

| Annex E Stress cracking TEST METHOD | (Abridgement) | |

| Annex F Resistance to separation from axial load TEST METHOD | Hold the axial force for the hold period from the relevant APLICATION part of ISO80369. | |

| Annex G Resistance to separation from unscrewing TEST METHOD | Apply an unscrewing torque to the collar as specified in the relevant APPLICATION part of ISO80369. | |

| Annex H Resistance to overriding TEST METHOD | Apply the torque specified in the relevant APPLICATION part of ISO80369 to the CONNECTOR under test. | |

| Annex I Disconnection by unscrewing TEST METHOD | Apply an unscrewing torque to the CONNECTOR under test at a rate of approximately 2 r/min until the CONNECTION separates. | |

Former ISO594

Conical fitting with a 6%(Luer) taper for syringes,needles and certain other medical equipment.

Part1:General requirements

| 4.Requirements | 5.TEST METHOD | |

|---|---|---|

| FITTING | TEST | |

| 4.1 Dimensions | – | 5.1.4 Axial force:5N |

| 4.2 Liquid leakage | 5.2.1 5.3.1.1 5.5.1 Torque: Not exceeting 0.1Nm Rotation: Not exceeting 90° Axial force: 27.5N Time: 5s | 5.2.3 (Abridgement) |

| 4.3 Air leakage | 5.3.1.2~5.1.7 (Abridgement) | |

| 4.4 Separation force | 5.4.2 (Abridgement) | |

| 4.5 Stress cracking | 5.5.2 5.5.3 (Abridgement) | |

Former ISO594

Conical fitting with a 6%(Luer) taper for syringes,needles and certain other medical equipment.

Part2:Lock fitting

| 4.Requirements | TEST METHOD | |

|---|---|---|

| FITTING | TEST | |

| 4.1 Gauging | – | 5.1 (Abridgement) |

| 4.5 Ease of assembly | (Abridgement) | |

| 4.2.1 Liquid leakage | 5.2.1 Torque: Not exceeting 0.12Nm Axial force: Not exceeting 27.5N | 5.2.3 (Abridgement) |

| 4.2.2 Air leakage | 5.3.2 5.3.3 (Abridgement) | |

| 4.3 Separation force | 5.4.2 Axial force: Not exceeting 35N Time: not less than 10s | |

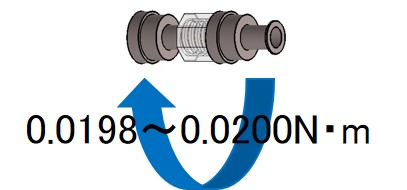

| 4.4 Unscrewing torque | 5.5.2 Unscrewing torque:0.02Nm Time: Nor less than 10s | |

| 4.6 Resistance to overriding | 5.7 Torque:Not less than 0.15Nm Time:5s | |

| 4.7 Stress cracking | 5.8.1 Torque: Not less than 0.12Nm Axial force: Not less than 27.5N Time:5s | 5.8.2 (Abridgement) |

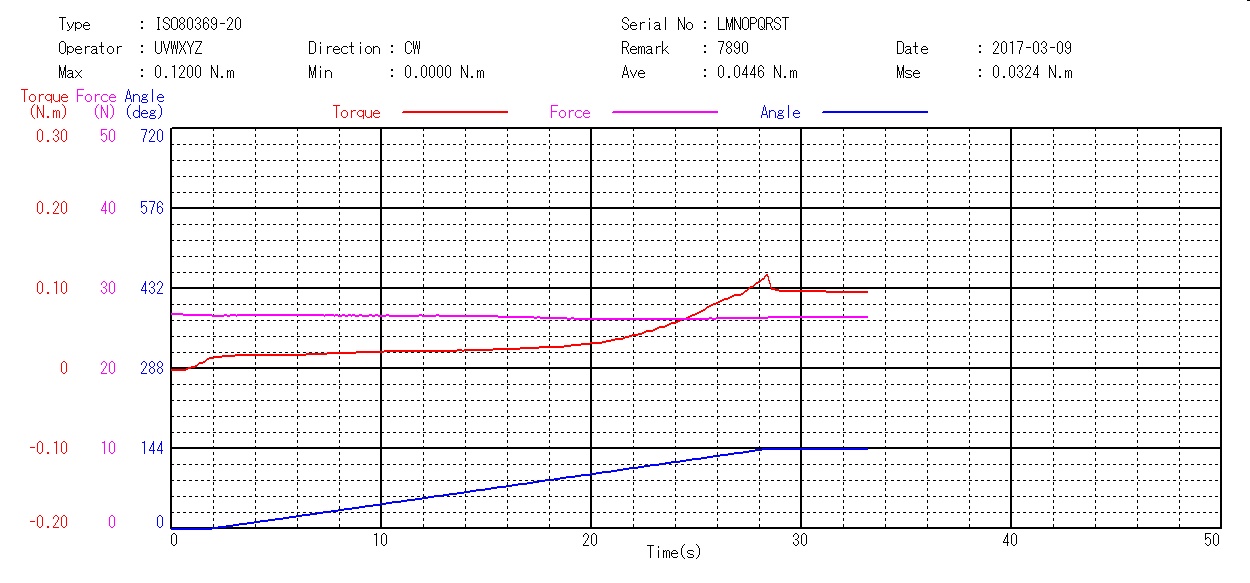

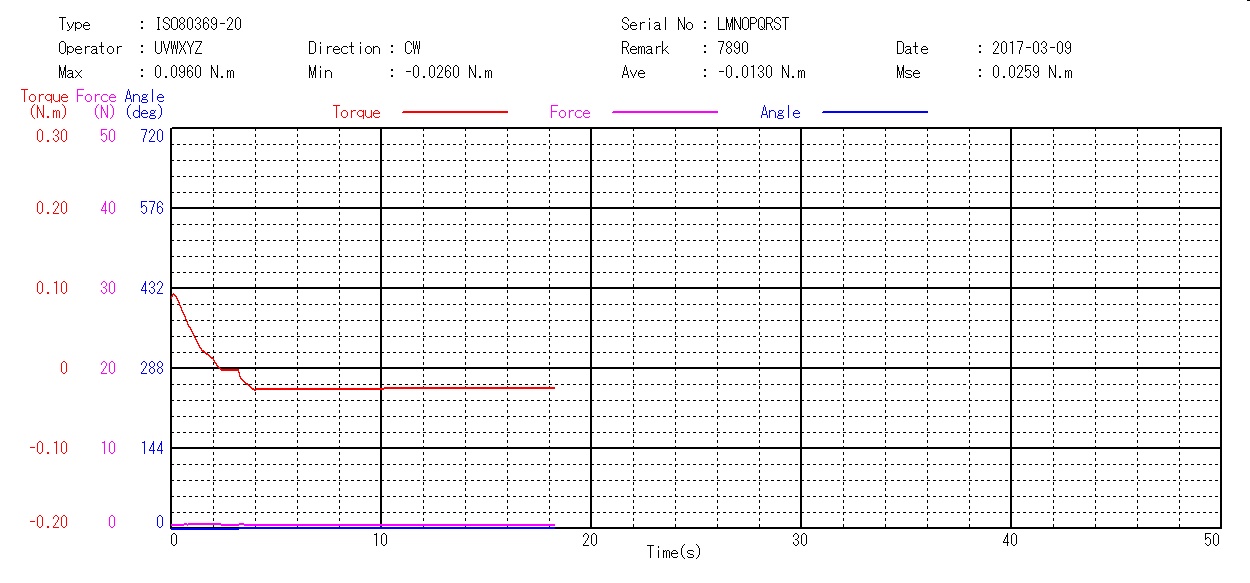

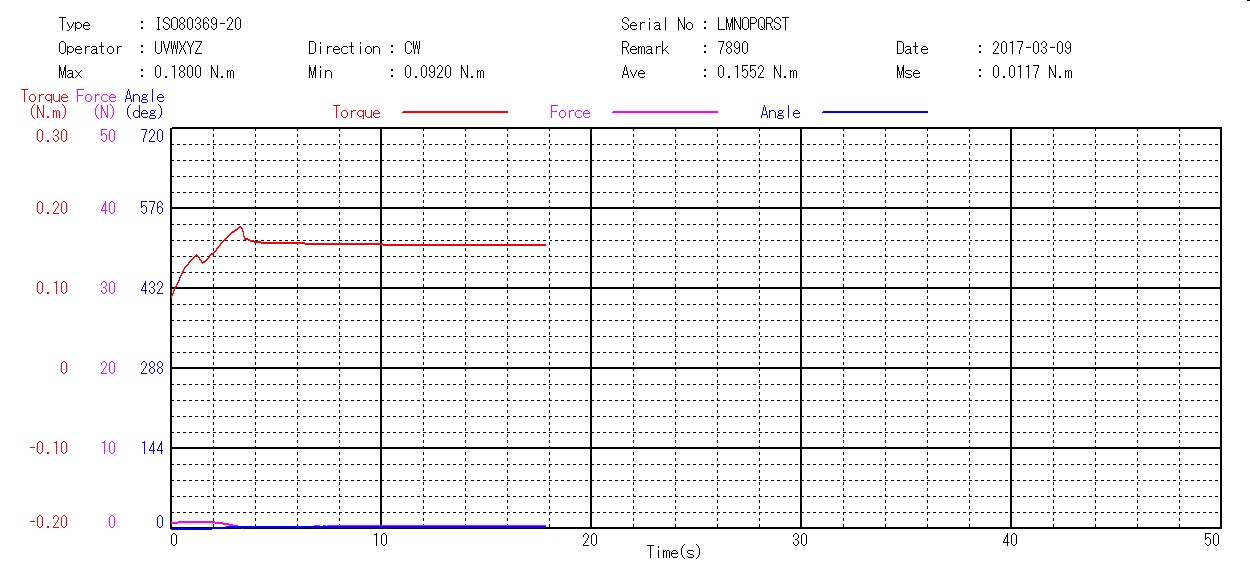

Measurement data example

FITTING

ISO80369-20

Resistance to separation from unscrewing TEST METHOD

ISO80369-20 Annex G

Resistance to overriding TEST METHOD

ISO80369-20 Annex H

inquiry

inquiry Quote

Quote Catalog Download

Catalog Download

Measurement system : +81-42-741-7690

Measurement system : +81-42-741-7690